The principle of the method exploits the nobility of gold, such that at high temperatures, gold does not react with chlorine, but virtually all contaminating metals do. The technique is practiced on a large scale (e.g. The separation is achieved by passing chlorine gas into a molten alloy. The standard procedure is based on the Miller process. Removal of silver is of particular interest since the two metals often co-purify. Parting is a process by which gold is purified to a commercially-tradeable standard, typically ≥>99.5%. The Albion process utilises a combination of ultrafine grinding and atmospheric, auto-thermal, oxidative leaching. Pressure oxidation is an aqueous process for sulfur removal carried out in a continuous autoclave, operating at high pressures and somewhat elevated temperatures. Bio-oxidation involves the use of bacteria that promote oxidation reactions in an aqueous environment. Roasting is used to oxidize both the sulfur and organic carbon at high temperatures using air and/or oxygen. The refractory ore treatment processes may be preceded by concentration (usually sulfide flotation). Bio-oxidation, such as Bacterial oxidation.Pre-treatment options for refractory ores include: This so-called "preg-robbing" carbon is washed away because it is significantly finer than the carbon recovery screens typically used to recover activated carbon.

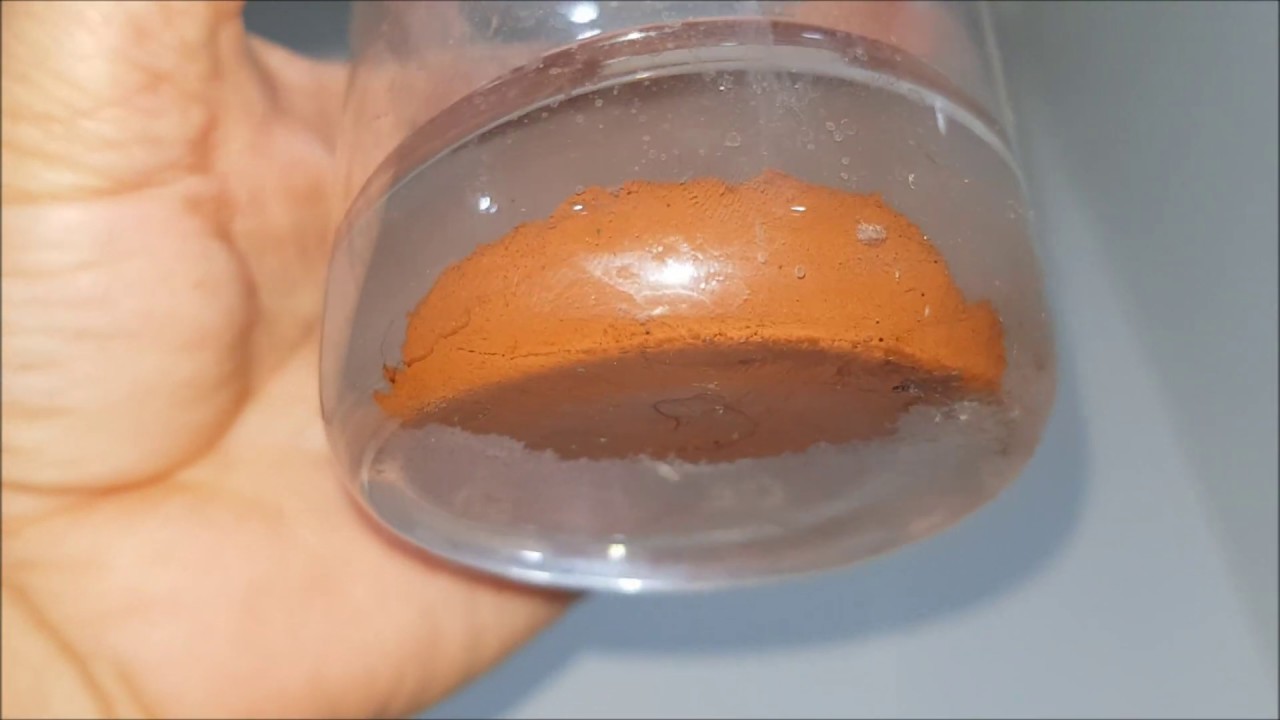

Organic carbon present in gold ore may adsorb dissolved gold-cyanide complexes in much the same way as activated carbon. Sulfide minerals are impermeable minerals that occlude gold particles, making it difficult for the leach solution to form a complex with the gold. A refractory ore generally contains sulfide minerals, organic carbon, or both. These refractory ores require pre-treatment in order for cyanidation to be effective in recovery of the gold. These ores are naturally resistant to recovery by standard cyanidation and carbon adsorption processes. The appearance is typical of very good gold-quartz ore.Ī "refractory" gold ore is an ore that has ultra fine gold particles disseminated throughout its gold occluded minerals. High-grade gold ore from a quartz vein near Alma, Colorado. Amalgamation with mercury was used to enhance recovery, often by adding it directly to the riffle tables, and mercury is still widely used in small diggings across the world.

Gravity concentration has been historically the most important way of extracting the native metal using pans or washing tables. Hard rock ores have formed the basis of the majority of commercial gold recovery operations since the middle of the 20th century where open pit and or sub-surface mining techniques are used. Hydraulic mining was used widely in the Californian gold rush, and involved breaking down alluvial deposits with high-pressure jets of water. Placer mining techniques since the mid to late 20th century have generally only been the practice of artisan miners. Gold mining from alluvium ores was once achieved by techniques associated with placer mining such as simple gold panning and sluicing, resulting in direct recovery of small gold nuggets and flakes.

Leaching through Bulk Leach Extractable Gold, or BLEG, is also a process that is used to test an area for gold concentrations where gold may not be immediately visible. Thiosulfate leaching has been proven to be effective on ores with high soluble copper values or ores which experience preg-robbing. Recovery from solution typically involves adsorption on activated carbon, the Carbon in pulp process. The extraction is called cyanidation or the cyanide process. 0.3% solution of cyanide in air, often repeatedly, and the aqueous extract is collected and refined further. "Black cyanide", a carbon-contaminated form of calcium cyanide (Ca(CN) 2) is often used because it is cheap. Sodium cyanide is produced on a billion-ton/year scale mainly for this purpose. The extractoin is conducted by dump leaching or heap leaching processes. Thus, the typical first step is comminution to expose the gold to the extracting solution. The principal technology involves the leaching of gold from the ore by teatment with a solution of cyanide. Thus, the main challenge is concentrating this trace amount. While the romantic picture of gold mining focuses on nuggets, the reality is that gold is typically recovered from ores containing >10 ppm of the metal. Chemical structure of potassium dicyanoaurate.

0 kommentar(er)

0 kommentar(er)